Rapid Prototyping and On-Demand Manufacturing for the Energy Industry

Optimize the prototyping and production of energy industry components at cost-effective prices.

Why Choose Us

Keep pace with the rapid technological advancements in both traditional and renewable energy projects. Fioria delivers exceptional energy component manufacturing through robust production capabilities. By combining technical expertise, extensive experience, and advanced technology, we provide high-quality, project-critical custom components tailored to the needs of the energy industry.

/01 High Quality Parts

Fioria specializes in custom manufacturing of industrial equipment components tailored to exact specifications. Our advanced capabilities allow us to produce parts with tolerances as tight as ±0.001 inches.

/02 Fast Lead Time

Receive quotes in minutes and parts in just days! Leveraging advanced manufacturing expertise and technical experience, our skilled engineers help reduce production cycle times by up to 50%.

/03 Engineering Support

As an ISO 9001:2015 certified organization, we ensure that your industrial equipment components are manufactured using the most appropriate materials and processes, including CNC machining, sheet metal fabrication, die casting, and more.

We Help From Prototyping to Production

01 Prototyping

Bring your early-stage medical designs to life with prototypes made from production-grade materials. Our process allows you to evaluate and refine your designs, ensuring full functionality and readiness for testing.

Early-stage design and material iterations

Prototypes using production-grade materials

Innovative models that closely resemble the final component

Rapid validation of functionality

02 Engineering Validation and Testing

Refine your robotics prototypes quickly and efficiently following rigorous engineering testing and performance validation. Our high-precision functional prototypes closely resemble the final product, offering a clear visual representation of your design and making it easy to identify potential issues.

Highly accurate functional prototypes

Comprehensive design and engineering solutions

Optimized design and material selection

03 Design Validation and Testing

Precisely evaluate the performance, functionality, and aesthetics of your medical product. Save time and resources by implementing design improvements during the prototype stage. Our expert design team offers detailed feedback on the manufacturing feasibility of your prototypes, assisting you in assessing both their performance and appearance.

High-quality prototypes for life-cycle testing

Comprehensive functionality and aesthetic evaluation

Surface finishing optimization and validation

04 Production Validation and Testing

Streamline your designs for large-scale production using our production-grade manufacturing capabilities and expert quality control. Benefit from valuable insights provided by our technical team’s feedback, enabling you to evaluate the manufacturability and suitability of your robotic parts and make final refinements for a smooth production process.

Agile and efficient low-volume production solutions

Thorough verification of manufacturing methods

High-quality precision parts with tight tolerances

Production-grade design adjustments

05 Mass Production

Effortlessly transition into mass production with fast delivery of end-use parts and seamless integration of your quality standards into Fioria’s manufacturing process. Elevate your custom robotics manufacturing with our advanced techniques. Our expert team ensures your products meet stringent quality and performance standards while keeping costs low and lead times short.

High-quality, production-ready components

Precision machining with tight tolerances

Superior post-processing operations

Comprehensive quality inspection and control system

Our Manufacturing Services

Fioria provides exceptional manufacturing capabilities, ideal for rapid prototyping and custom production runs. With our own factory and a broad Chinese manufacturing network, we efficiently deliver complex, high-quality parts.

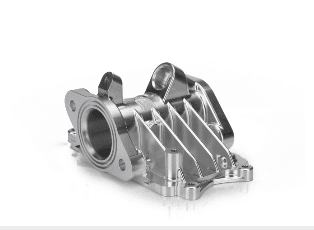

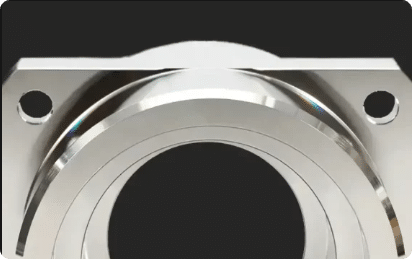

CNC Machining

Produce precise, intricate designs through milling, turning, and post-processing, perfect for both complex prototypes and functional metal components.

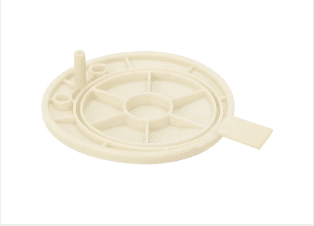

Injection Molding

Quickly manufacture molded parts and bridge tooling, optimized for high-volume production with consistent quality.

Sheet Metal Fabrication

Offers flexibility in shaping precise metal components customized for diverse applications, ensuring both adaptability and accuracy.

3D Printing

Quick and adaptable, this technique efficiently produces complex geometries from a variety of materials, ideal for innovative designs.

Extrusion

An economical method for manufacturing consistent, elongated parts from various materials, maximizing production efficiency and material utilization.

Die Casting

Perfect for high-precision metal part manufacturing, this process excels in large-scale production, delivering consistent quality across every piece.

Vacuum Casting

Ideal for producing high-quality prototypes or end-use parts in small batches, offering outstanding detail and surface finish.

Wire EDM

Delivers exceptional precision when cutting intricate and hard materials, making it perfect for detailed and complex components.

Automotive

Materials & Surface Finishes

Materials

We offer a broad selection of materials, including metals, plastics, and composites.

Surface Finishes

We provide high-quality surface finishes that improve part durability and appearance, suitable for applications needing smooth or textured surfaces.

Applications of Automotive Parts

From solar panel components and wind turbine parts to valves and more, Fioria efficiently manufactures parts for the energy industry. By combining custom manufacturing solutions with robust quality management systems, we ensure your parts reach the market quickly and reliably.

Generator components

Jigs and fixtures

Valves

Rotors

Turbine components and housings

Bushings

Fasteners and connectors

Sockets

Hydraulic components

Fit check gauges